Food waste to drug delivery platform: Hydrogel development from durian rinds for topical application

Introduction

Durian, seasonal tropical fruit in Malaysia, is named the king of fruits due to its large size, pungent odour and thorny rinds. While the flesh is enjoyed for its sweet fragrance, the rinds that occupied more than half of the whole fruit are usually disposed of as typical household food waste which ends up in landfills. This not only poses problems for the environment but also cause waste for this natural source of cellulose. The potential source of cellulose from this non-woody biomass can be used to develop drug delivery platforms such as hydrogels.

Hydrogels are hydrophilic and water-insoluble polymeric systems. On exposure to a compatible solvent, hydrogels can swell and entrap a high amount of solvent within their interstitial spaces. This can serve as a good drug reservoir for drug delivery to the skin. A high drug concentration in the hydrogels creates a large concentration gradient of drugs across the skin, allowing more drugs to penetrate the skin easily.

While hydrogels are usually prepared from synthetic polymers, the use of native cellulose for hydrogel development is less explored. Cellulose is a linear D-anhydroglcopyranose chain where each glucose unit is connected by β-1,4-glycosidic bonds. Owing to an abundance of hydroxyl groups, cellulose chains can be physically or chemically crosslinked to form 3D polymeric network of hydrogels. This is an attractive characteristic for cellulose as a flexible biomaterial for drug delivery. Recognising the importance to valorise the food waste like durian rinds for value-added products, the current work aims to optimise the hydrogel development from durian rinds for topical drug delivery

Experimental methods:

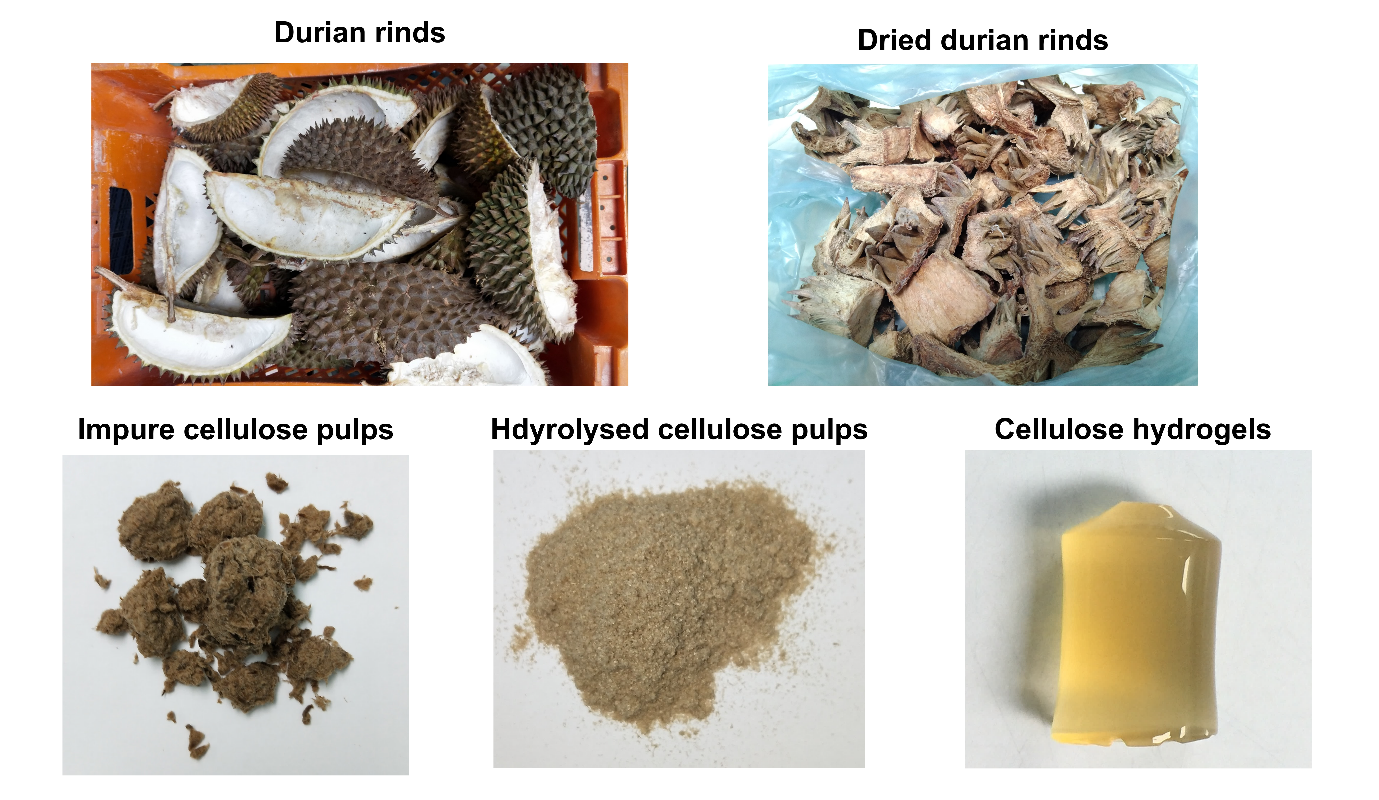

Cellulose was obtained from hydrolysis of unbleached pulps extracted from durian rind (Durio zibethinus) using an in-house method. Cellulose (2 – 4% w/v) was solubilised in different combinations of alkali solvent containing sodium hydroxide, NaOH (6 – 8% w/v) and urea (4 – 6% w/v) prior to crosslinking. Cellulose solubility, volume and index of viscosity of cellulose solutions were measured. Crosslinked hydrogels were soaked in distilled water to remove unreacted chemicals before drying for storage. Re-swollen hydrogels in distilled water were evaluated for gel fraction, swelling index and gel strength. Ex vivo skin permeation study was performed with re-swollen hydrogels in aqueous caffeine (1% w/v) solution with 50% v/v of propylene glycol.

Results

Cellulose solubility was generally recorded at 35 – 60% based on the initial cellulose content. The cellulose solubility was found to be higher with a lower cellulose content. With this, the volume of solubilised cellulose solution was also higher. Even though a high NaOH content is associated with higher cellulose solubilisation, this was not reported in this study. The cellulose solubility peaked at 7% w/v of NaOH at lower cellulose content. The influence of cellulose content on the solubilisation is more significant than the solvent compositions. In spite of this, no difference was found for the index of viscosity (~0.1 N/s) of all cellulose solutions.

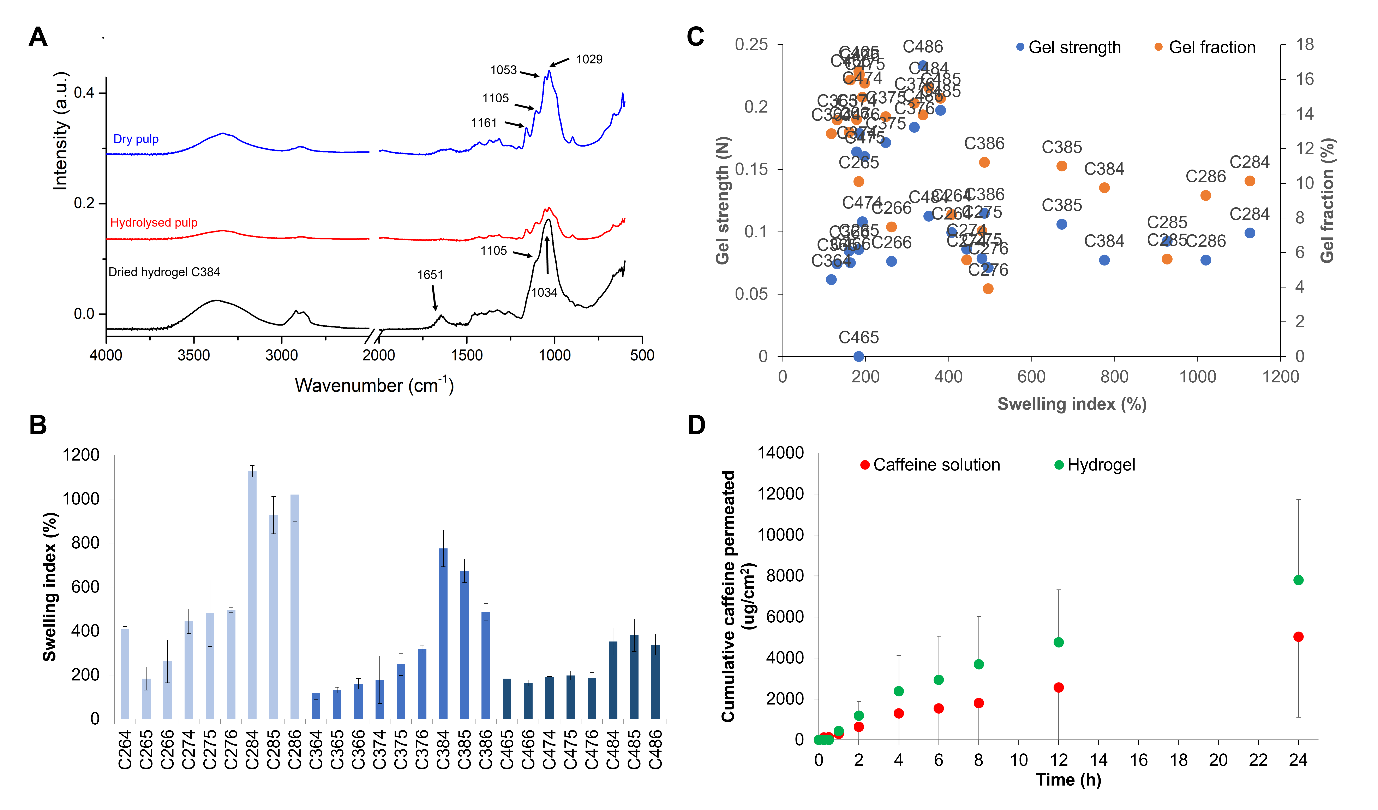

FTIR spectra of dried hydrogels confirmed the formation of a crosslinked network via etherification by showing the C-O-C stretching vibrations at 1034 cm-1. While the O-H bending peak appeared at 1651 cm-1 showed the presence of absorbed water remained in the hydrogels. The swelling index of hydrogels increased with NaOH content but decreased with cellulose content. The highest swelling index (900 – 1000%) was achieved in hydrogels prepared with 2% w/v of cellulose. However, highly swollen hydrogels were observed to have a weaker gel strength. This is believed due to a lower degree of crosslinking as reflected in the low gel fraction for these samples. Urea showed no effect on the parameters measured.

Due to the fragility of highly swollen hydrogels, the hydrogel with 3% w/v of cellulose, 8% w/v of NaOH and 4%w/v of urea with a swelling index of 775% was selected for ex vivo permeation study. The hydrogels (150 – 160 µg/cm2 of caffeine) showed a much higher permeation (7795 ± 3921 µg/cm2) than a similar drug solution (5031 ± 3933 µg/cm2) dosed at 200 µg/cm2. Although the variations were not statistically significant, the amount of caffeine loaded was lower for the hydrogel. This can be related to the occlusive effect of hydrogels in enhancing drug transport into the skin.

Conclusions

In this proof-of-principle study, we demonstrated the potential of developing cellulose hydrogels from durian rinds which are common food waste during durian seasons. Optimisation of hydrogel formulation is necessary to obtain a highly swollen and strong hydrogel that is suitable for topical application. The hydrogels developed are at advantage to enhance the delivery of caffeine than in the solution form. This fundamental understanding of hydrogel development from durian rinds warrants the use of other non-woody biomasses which are usually low value for drug delivery design.

Acknowledgements

Choon Fu Goh would like to thank Universiti Sains Malaysia for funding the work through Research University Individual (RUI) Grant Scheme with Project No: 1001/PFARMASI/8012320, Project Code: UO1822 (Reference No: 2019/0589). Choon Fu Goh also would like to thank MyCRS for awarding MyCRS Young Scientist Award 2021 and CRS for CRS Young Scientist Registration Grant Award 2021 to present the work during CRS Virtual Annual Meeting 2021.

References

L.C. Wong, C.P. Leh, C.F. Goh, Designing cellulose hydrogels from non-woody biomass, Carbohydr. Polym., 264 (2021) 118036.

S. Gan, S. Zakaria, C.H. Chia, R.S. Chen, A.V. Ellis, H. Kaco, Highly porous regenerated cellulose hydrogel and aerogel prepared from hydrothermal synthesized cellulose carbamate, PLoS ONE, 12 (2017) e0173743.

Y.H. Chong, W.R. Wan Daud, B.T. Poh, M. Ibrahim, C.P. Leh, Application of Photo, Peracetic Acid, and Combination Pre-treatments in Improving Totally Chlorine-Free Bleaching Selectivity, Bioresources, 10 (2015) 4110-4125.

H. Kaco, S. Zakaria, N.F. Razali, H.C. Chin, L. Zhang, S.M. Jani, Properties of cellulose hydrogel from kenaf core prepared via pre-cooled dissolving method, Sains Malays., 43 (2014) 1221-1229.

C.P. Leh, W.D.W. Rosli, Z. Zainuddin, R. Tanaka, Optimisation of oxygen delignification in production of totally chlorine-free cellulose pulps from oil palm empty fruit bunch fibre, Ind. Crops Prod., 28 (2008) 260-267.